Copper Refinery Souvenirs

(c) Antique Metalware Society

Small extracts can be used with acknowledgements to 'Oldcopper.org' website.

Helpful comments are very welcome.

Copper refineries convert ore with a high mineral content to pure copper in forms that can be bundled in 25 ton lots and sent anywhere for trade or use in the production of copper and copper alloy products. In the good times when copper prices are high, they may make more money than the foundries and fabricators so can afford to produce interesting items as promotional gifts. All refineries work to similar agreed standards of purity to satisfy the trading requirements of the London (LME) and American Metal (AMEX) Exchanges. More than half of the production is of high grade to meet the needs of the electrical industry. Therefore refineries have a great pride in the quality and reputation of their own brand and the extent to which its purity and conductivity is better than standard.

Production was normally limited to ‘Refinery Shapes’ such as wirebars, ingots, cakes or billets; these products were used as feedstock by wire mills, sheet mills and foundries. The Refineries have their own three-letter brand abbreviations to identity their copper and these are often incorporated in their gifts. Small souvenirs were some of the most difficult to make when refineries used traditional extraction processes. If you know and admire the products normally made, you might think that refinery souvenirs do not look crude but are ideal for display. They are much less common now that production methods are frequently by continuous melting and casting, more integrated and environmentally friendly. Refinery souvenirs should be treasured.

|

Souvenir small copper wirebar made by Enfield Copper Refiners during the 1960s while they were still casting wirebar copper for rolling to copper rod. The top of the casting is fully convex which is typical of a good tough pitch copper. Length 140mm (5½") Weight 200g (7oz) each. |

|

Section of wirebar from Enfield Copper Refiners. Originally it was polished, etched to show the grain structure as cast and then lacquered. Over forty years the etching has been slightly obscured by tarnishing under the lacquer. |

|

A ‘Black Museum' item from Enfield Copper Refiners, Middlesex. This is a section of a sample taken from a 180ton open hearth refinery furnace during the 24hr cycle and before it was ready for pouring. The 'gassiness' of the copper showed that it needed further 'poling' by having the melt stirred with long poles made of damp, green wood that bubbled fiercely under the copper and removed excess hydrogen. Normally the refinery foreman would not have needed to section the sample - just feel the weight in his hand to check that it was solid copper. This type of souvenir was invaluable as an example that is better than a thousand words. With the demise of the process and when generations move on in the industry it unfortunately tends to loose perceived value completely and may end up being recycled with other scrap instead of preserved with its history. Length 125mm (5”), diameter 44mm (1¾”). |

|

Miniature anode cast as a gift for special visitors to Ndola Copper Refinery in Zambia c1981. From the fire refining stage of the purification of copper anodes are cast in roughly square shape with ears at two corners to enable them to be hung between the starter plates that build up to cathodes in an electrolytic refining tank. This has a width, without the ears of 73mm (2⅞") and a weight of 600g whereas production anodes would be about 1,000mm square and weigh about 100kg. |

|

|

|

A sample of electrolytically refined copper neatly cropped from a cathode of 99.95+% pure metal. The ore was mined at Mufulera and smelted at Ndola Refinery owned by the Rhodesian Selection Trust (RST International Metals) in what was then Northern Rhodesia c1965. The nodules were entirely typical at that time but process improvements have resulted in smoother cathodes being produced now. Length 160mm (6¼") Weight 1kg, cut from a cathode of 100kg. |

|

A strictly functional ashtray cast at Enfield Copper Refiners in high conductivity copper and still showing the as-cast purple oxide finish. These were specially cast as souvenirs for guests at an open day in 1969. The underside is covered with a protective green baize. With a wall thickness around 5mm (5/16”), it is not surprising that it weighs a hefty 860g (1lb 14oz). |

|

When the fire-refining of copper was the main process it was usual to cast it to the form of wirebars for subsequent hot rolling and cold drawing to wire. This souvenir was made for invited guests at the commissioning of the new Southwire Continuous copper wire rod plant on the 17th October 1974 at Enfield Rolling Mills, Middlesex. Copper cathodes were then melted in a shaft furnace and continuously poured to give the smaller cast shape shown which was then immediately rolled on to the 6mm diameter size of the top coil. The base is marked on the sides 'First SCR Coil’. |

|

This is a section from a wirebar and a miniature souvenir gift made for a previous occasion. Wirebars could be 60-225kg in weight, typically 100-125kg and could only be rolled into rod of that size pieceweight before joining for subsequent wiredrawing. The continuous process avoided these joints that gave potential breaks later. |

|

Copper ashtray from IMI Refiners (James Bridge Copper Works, Walsall), December 1985 575g 'This copper ashtray is a memento of your visit to IMI Refiners. It has been made from a slice of 92mm diameter DHP copper billet cast on our horizontal casting machine. The cast surface is typical of our horizontal product showing the witness of the oscillation of the mould. |

|

Promotional ash tray made for British Copper Manufacturers Ltd.140mm dia. The company was formed in 1924 by the amalgamation of the two major copper smelting firms in Swansea, Messrs. Vivian and Sons; and Messrs. Williams Foster and Company and Pascoe Grenfell and Sons Limited. Messrs Vivian and Sons had been founded by John Vivian, a Cornish mine owner in the early nineteenth century. Messrs. Williams Foster and Company and Pascoe Grenfell and Sons Limited had been formed out of two Swansea firms, Messrs. Pascoe Grenfell and Sons and Messrs. Williams, Foster and Company in c1892. BCM was taken over in 1927 by ICI Ltd and Yorkshire Metals to form Yorkshire Imperial Metals Ltd. which included other factories in Yorkshire and Lancashire. |

|

This is a round copper paperweight from the Anaconda Company. It has BUTTE stamped on the top of it. Base diameter approx. 2"; about 1" high. In 1899, Marcus Daly merged with Rockefeller's Standard Oil Company to create the Amalgamated Copper Mining Co. In 1910, the company changed its name to the Anaconda Copper Mining Company, after it bought up many smaller companies. The original mines at Butte, Montana are now a pit over a mile long, nearly a mile wide and 1800 feet deep. Mining ceased here in 1982 but the company owned many others worldwide. Since 1977 it has been a subsidiary of Atlantic Richfield Company (ARCO). |

|

Anaconda Brass started as J.F. Brown’s Copper & Brass Rolling Mills, in 1919, located on Birmingham Street, New Toronto, Ontario. Anaconda acquired the mills soon after in 1922. In its last few years of operations, it was Arrowhead Metals. The plant closed its doors for good in 1989. The item is an excellent quality two-part casting made at the refinery in high conductivity copper and shows no signs of porosity or other significant casting defects. The surface finish is as-cast copper oxide. On the base is the lettering 'From mine to Consumer' and to it riveted the arrow head and part shaft, lettered 'Anaconda' on both sides. |

|

Anaconda Copper Mine Arrowhead Key Chain Fob. |

|

4X4-inch etched slab cut from an Anaconda copper wirebar (Anaconda, Montana smelter). Shows crystallization pattern with solidification from all four walls, typical of vertical casting. (Thanks to Fred Barnard) |

|

Star, from the now-closed copper smelter at Cananea, Sonora, Mexico. Built by Anaconda Mining (U.S., company in the late 1920's. The property was nationalized by the Mexican government in 1976, is now operated by a Mexican company, Mexicana de Cobre. The smelter was closed about 2000, but the enormous mine is still going strong, and ships copper mineral concentrated to another smelter at Nacozari, Sonora, operated by the same company, near their Nacozari mine. Some older memorabilia from this mine carries the 4-C initials, CCCC = Cananea Consolidated Copper Company. (Thanks to Fred Barnard) |

|

Anaconda Arrow cast as a dish and compared with a sixpence coin for size.

(Thanks to Fred Barnard) |

|

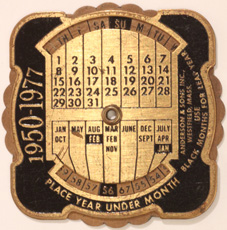

Anaconda Pocket Perpetual Calendar by The American Brass Company. It is 38mm (1½") square and covers the years 1950 to 1977. |

|

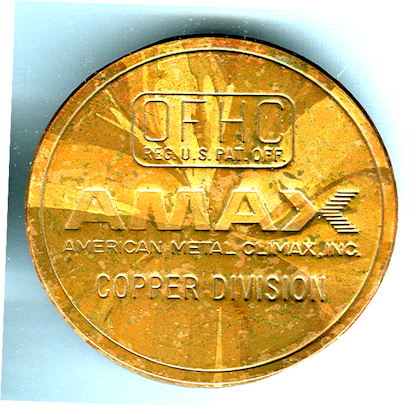

3 1/2-inch diameter etched slab from a circular wirebar of OFHC copper (oxygen-free, high-conductivity copper) from AMAX Copper. Also shows crystallization pattern. AMAXC produced copper in Arizona. (Thanks to Fred Barnard) |

|

A souvenir pin tray from Bingham Canyon Mine, managed by Kennecott Copper Mine showing typical scenes including the mine, a loader, an electric mine locomotive, two miners with an early pneumatic drill and the old town. Interestingly, the tray looks as though it is made as an electroform, a similar process to the electrolytic refining method used to produce their cathodes. However a gentle scrape reveals that it is copper plated zinc sheet. Some of these are marked on the back 'Made in Japan'. Height 115mm (4½"). Weight 85g. |

|

A circular dish with the initials C & H. This is from Calumet & Hecla's copper smelter at Lake Linden on the Keweenaw Peninsula of Michigan's Upper Peninsula. Based on the combined name of C & H and the smelter's lide, this was made sometime between 1923 and 1968. (Thanks to Fred Barnard) |

|

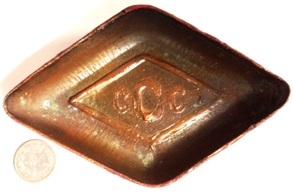

Half of a 5" souvenir ingot paperweight, copper, with lozenge-CCC from Chile Copper Co. (Calama smelter. (Thanks to Fred Barnard) |

|

A lozenge-shaped dish, marked CCC. This stands for Chile Copper Company, also founded by Anaconda in the late 1920's. The smelter is located at Calama in northern Chile, and serves the enormous Chuquicamata Mine and others in the environs. Anything with the lozenge-CCC logo dates from the Anaconda period, 1926-1971. In 1971 the complex was nationalized by the Chilean government, and is now operated by CODELCO (Corporacion Del Cobre). (Thanks to Fred Barnard) |

|

An ingot by Copper Range Company. This company operated in the native-copper ores of the Upper Peninsula of Michigan, their smelter dates I believe were 1955-85. They sold all their copper in poured unrefined ingots. The CR on the end stands for Copper Range (Company). Length 19”, weight 49 lb. (Thanks to Fred Barnard) |

|

WP small crude cast paperweight, only 3 1/2 inches long, weight 3 1/2 oz. This was "lunchbox" stuff, with WP standing for White Pine, which was the name of the only mine operated by Copper Range Co. The lunchbox stuff usually says "WP" and the commercial ingots say "CR". (Thanks to Fred Barnard) |

|

A copper tray found in a spoil dump next to a mine at Jerome, Arizona. Most of the mines in Arizona tried casting souvenirs at some time. Some had no embossing but this reads ‘UVX’, the original name for the United Verde Extension and Jerome Arizona mine, before it was renamed ‘Jerome Arizona’. |

|

Copper jewellery box from the KGHM Polska Miedź Lubin Mine, Poland. This is the third largest copper miner with its own mines in Poland. |

|

Tie Pin from Metal Marketing Corporation (MEMACO) of Zambia, now owned by Zambia Consolidated Copper Mines Ltd (ZCCM). |

|

Two Morenci copper refinery ashtrays that come from the Morenci, Arizona smelter that was closed many years ago. Originally these were made and given to special guests as gifts. The red colour is typical of the oxide on cast copper. The heart shape is 70mm (2¾") square and the Arizona state shape says ‘Morenci ARIZ’ in the bottom. It measures 75 x 83mm (3 x 3¼"). |

|

Copper ashtray machined from wirebar section in 1964 from the Mufulera (MCM) mine, Northern Rhodesia, now Zambia since 1964. |

|

QF&R - Quincy Foundry and Refinery, 22 lbs. Also Upper Peninsula of Michigan, smelter operated 1898-1971. There has been no copper production in Michigan since closure of the White Pine Mine in 1985. Previously, there had been numerous companies operating scores of mines, with a dozen or so smelters. Nearly all Michigan copper was shipped in cast ingots, as it contained some silver, and was desirable for its resulting higher electrical conductivity. (Thanks to Fred Barnard) |

|

Utah Copper Co. promotional paper weight in the shape of an ingot. Length 74mm (c3"). Utah version began on June 4, 1903 when the original Utah Copper Company (UCC) was created to mine and process low grade copper ore found in a mountain in Bingham Canyon, about 25 miles southwest of Salt Lake City. Steam shovels began working on the mountain in 1906. For the next 100 years, shovels, trains and trucks converted that mountain into the world famous Bingham Canyon Mine, a huge open pit copper mine that is more than three-quarters of a mile deep and more than 2 3/4 miles wide across the top and still growing. In 1915, Kennecott Mines became Kennecott Copper Corporation, which purchased a 25 percent interest in the Utah Copper Company and acquired all assets and property in 1936 forming Kennecott Utah Copper (KUC). In 1947, Utah Copper Company was dissolved and became the Utah Copper Division of Kennecott Copper Corporation. In 1981, Standard Oil of Ohio (SOHIO) purchased Kennecott, and in 1987 British Petroleum bought SOHIO’s interests. In 1989, RTZ Corporation, now known as Rio Tinto, became the owner of Kennecott Utah Copper Corporation. |

After